ONESTEP AI and FANUC Revolutionize Industrial Automation

At ONESTEP AI, our mission is to bring the power of artificial intelligence to the heart of the manufacturing industry. Our collaboration with FANUC, a global leader in industrial robots and CNC systems, represents a significant step toward achieving this goal. FANUC’s more than 60 years of experience in robotics, combined with our AI expertise, is transforming robots from simple tools into intelligent, adaptive systems that are critical to the future of Industry 4.0.

This innovative partnership was showcased at the VISION 2024 fair in Stuttgart, Germany, where ONESTEP AI and FANUC demonstrated how AI vision systems can enhance the capabilities of industrial robots. By integrating ONESTEP AI’s platform with FANUC’s robots, we are delivering smarter, more flexible manufacturing solutions that optimize operational efficiency and quality control.

Implemented Solutions

The collaboration between ONESTEP AI and FANUC Poland resulted in the development of an external AI vision system for industrial robots. The ONESTEP AI platform enabled the creation of an independent information flow - from the camera (serving as an information source), through product model training, the generation of a flow graph (AI’GORITHM) running on a standalone edge device, to the integration with the robot as an executing unit.

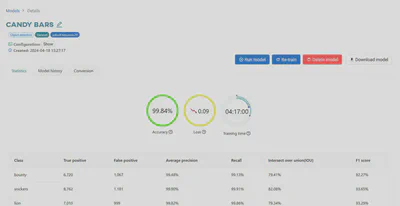

The process starts with building models of candy bars, captured by a camera mounted above the station. This step is not only for detecting anomalies, but also for classifying those anomalies. By training a model of a correct product, any deviations in appearance are flagged as defects. This prepared dataset is uploaded to the ONESTEP AI platform, which uses its tools to create a training dataset.

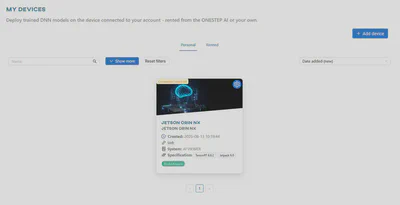

The next step is to train the model using predefined frameworks and models. For those without experience in neural network training, predefined settings are available. Advanced users can use the platform’s Advanced Mode to manually adjust parameters. After training, the model’s accuracy is tested using the platform’s hardware, such as the Jetson Orin NX device. The final steps include using AI’GORITHM to create an algorithm and integrating the system with a FANUC robot for production deployment.

Key Features and Benefits

- Operational Flexibility: Application and reconfiguration times reduced from days to hours.

- Productive Efficiency: Adaptive robotic movements and real-time object recognition increased throughput by 30%, ensuring continuous operation with minimal downtime.

- Application Expansion: Suitable for diverse tasks like contamination management and precision handling.

- Quality Control: Improved anomaly detection systems achieved 97% accuracy.

- Latency and Precision: Real-time analysis and high-precision movements through optimized algorithms and sensor fusion.

- Portability and Robustness: Modular architecture with consistent performance under varying conditions.

Applications

- Manufacturing: Streamlined assembly and quality control

- Food and Beverage: Hygienic sorting and packaging

- Logistics: Accelerated order processing and inventory management

- Electronics: Precise assembly of small components

- Automotive: Improved parts assembly and stock control

- Recycling: Optimized sorting for waste processing

Future Prospects

The collaboration between ONESTEP AI and FANUC opens new frontiers in industrial automation, focusing on enhancing robot capabilities through advanced computer vision and AI integration. This partnership paves the way for unprecedented advances in real-time, precision robot control under dynamic environmental conditions.

By combining AI with robotics, we are not only transforming traditional manufacturing processes, but also setting new standards for quality control. As robotic systems become more intelligent and adaptable, they drive efficiency, flexibility, and precision in production. This innovation positions ONESTEP AI and FANUC as leaders in Industry 4.0, with significant impact on sectors such as electronics, automotive, and pharmaceuticals. Market forecasts predict a 15% growth in the industrial robotics sector over the next five years, driven by breakthroughs in AI-robotics integration and intelligent automation. Smarter systems will enable robots to automatically adjust to the position and orientation of components, optimizing execution speed while maintaining accuracy.

As cycle times decrease, robots will be able to handle a wide variety of components more quickly, ensuring that precision is never compromised. This dynamic approach will also improve the handling of product variants, a key factor in industries with high customization requirements.

In the future, human-robot collaboration will become more seamless. Intuitive interfaces will simplify robot programming, allowing operators without specialized knowledge to control complex robotic movements. Real-time visualization of production and quality data will enable faster decision-making and more efficient process management. In addition, automatic calibration of vision systems will ensure that robots maintain high accuracy even as they adapt to new products.

This exciting future of robotics promises to redefine the way industries approach automation, offering smarter, more adaptive solutions that are ready for the challenges of tomorrow’s manufacturing world.

Video

Explore this innovative solution further by watching the ONESTEP AI and FANUC Integration video:

>